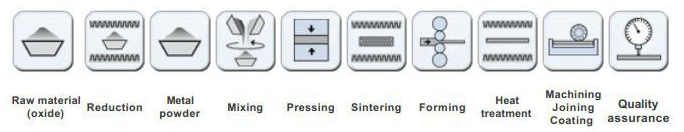

Specifications

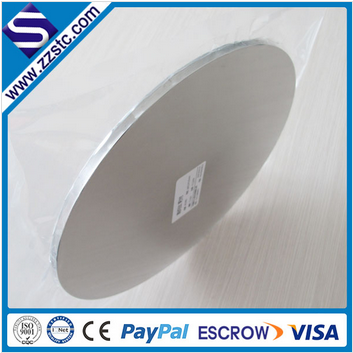

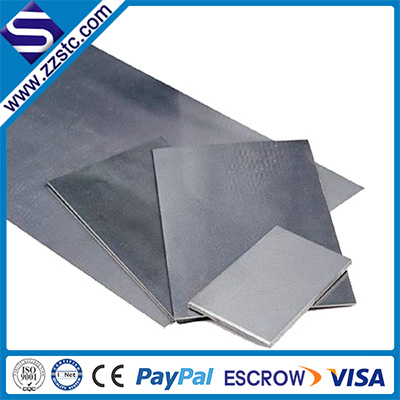

1.Chromium Plate2.Density:7.19g/cm3

3.Purity:99.5%,99.7%,99.9%,99.95%

4.Thickness:1.0mm -35.0mm

5.Standard:ASTM, ISO9001

- Chromium: For brilliant results.

Chromium is a lightweight blue-silvery white metal. The name chromium comes from the Greek "chroma" and means color. Thanks to its very high corrosion resistance against many different acids and bases as well as hot gases, chromium is a popular material for all types of protective coating.

In combustion equipment, chromium is used as a wear-resistant coating to increase the service life of specific components. As a component in high-temperature fuel cells, our chromium also performs brilliantly. Alongside these applications, our chromium is also used as a brilliant decorative coating for operating elements on appliances or for jewellery.

- Guaranteed purity.

You can rely on our quality. We produce our chromium products ourselves – from the metal powder right through to the finished product. As our input material, we use only the purest chromium powder. This ensures that you benefit from a very high level of material purity.

1. We guarantee that our chromium (HP) has a purity of 99.8 %.

According to a chemical analysis, the remaining content consists of the following elements:

| Element |

Guaranteed |

| Fe | 1500 |

| Mo | 50 |

| W | 50 |

| others | 300 |

| Si | 500 |

| O | 1000 |

| N | 200 |

| C | 300 |

2. We guarantee that our chromium (UHP) has a purity of 99.95 %.

According to a chemical analysis, the remaining content consists of the following elements:

| Element |

Guaranteed |

| Fe | 300 |

| Si | 100 |

| W | 50 |

| Mo | 50 |

| C | 100 |

| N | 200 |

| O | 300 |

- Excellent wear resistance. Beautiful optics.

Given its unique properties, it comes as no surprise that our chromium is used for some very special industrial applications, for example as a coating material in a variety of processes:

As a chromium nitride hard material coating applied to moving parts, the material provides reliable protection against wear and abrasion. In addition, chromium gives brilliance and sheen to watches and fittings of all types. At the same time, chromium protects against corrosion.

- Pure chromium - or maybe an alloy? It's your choice.

We prepare our chromium to perform perfectly in every application. We can determine the following properties through the addition of various alloys:

- Physical properties (e.g. melting point, vapor pressure, density, electrical conductivity, thermal conductivity, thermal expansion, heat capacity)

- Mechanical properties (e.g. strength, fracture behavior, ductility)

- Chemical properties (e.g. corrosion resistance, etchability)

- Workability (e.g. machining, formability, weldability)

- Structure and recrystallization properties (e.g. recrystallization temperature, proneness to embrittlement, aging effects, grain size)

And there's more: By using our own customized manufacturing processes, we can modulate various other properties of chromium and chromium alloys across a wide range of values.

| Name of Material |

Chemical Composition (percentage by weight) |

| Cr (High Purity) | >99.8% |

| Cr (Ultra High Purity) | >99.95% |

| CFY |

<95% Cr 5% Fe Yttrium |

| ITM |

<74% Fe 26% Cr (Mo, Ti, Y2O3) |

- Specification of Chromium Plate

|

Chromium Products |

||

|

Grade: Cr1, Cr2 |

||

|

Production |

Standard |

Size |

|

Chromium bar /rod |

ASTMB456 |

dia(6-120mm)*(50-2500mm) |

|

Chromium wire |

ASTMB456 |

dia(0.5-6mm)*L |

|

Chromium plate /sheet |

ASTMB168 |

(thkness1.0-35mm)*(W50-500mm)*(L10-2000mm) |

|

Chromium tube/pipe |

ASTMB408 |

OD(6-100mm)*(L50-3000mm) |

|

Chromium foil |

ASTMB168-98 |

thkness0.05-6mm*W20-150mm*L |

Our commitment to quality is in everything we do, from the materials we use to our manufacturing process.