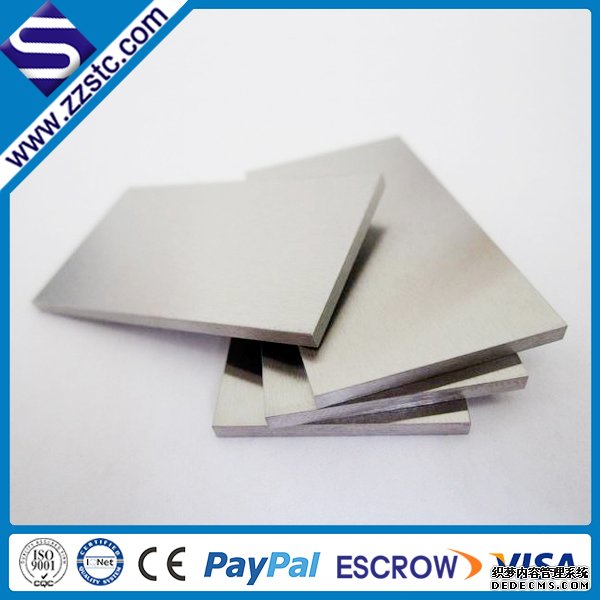

Cross Rolled Molybdenum Plate Innovations

We talked about cold rolling molybdenum sheet application before. Today, we will discuss cross rolled molybdenum plate innovations.

The way of rolling has great effect on anisotropic of molybdenum plate. Reversal rolling can not only reduce anisotropic of molybdenum sheet, but also can decrease fragility and ductility transition temperature of molybdenum plate.

Cross rolled molybdenum plate gets over these defects.

There followings are some cross rolled molybdenum plate innovations and advantages:

Hot rolled billet - stress relief annealing - warm rolling - stress relief annealing - alkali wash - one cold rolling - stress relief annealing - two cold rolling - stress relief - alkali wash - end rolling annealing - cut.

Advantages:

1. Appropriate reversal rolling (cross rolled)can effectively improve anisotropic of rolled molybdenum plate and enhance molybdenum plate over-all properties.

2. Compared with unidirectional rolling technics, cross rolled molybdenum plate’s mechanical properties in vertical and horizontal two directions are better. In the case of matching strength, the elongation rate has been significantly improved.

3. Cross rolling will strengthen the uniformity of the internal structure of molybdenum plate. This kind of structure can maintain good plasticity in the further processing and has good deep drawing performance.

The way of rolling has great effect on anisotropic of molybdenum plate. Reversal rolling can not only reduce anisotropic of molybdenum sheet, but also can decrease fragility and ductility transition temperature of molybdenum plate.

Cross rolled molybdenum plate gets over these defects.

There followings are some cross rolled molybdenum plate innovations and advantages:

Hot rolled billet - stress relief annealing - warm rolling - stress relief annealing - alkali wash - one cold rolling - stress relief annealing - two cold rolling - stress relief - alkali wash - end rolling annealing - cut.

Advantages:

1. Appropriate reversal rolling (cross rolled)can effectively improve anisotropic of rolled molybdenum plate and enhance molybdenum plate over-all properties.

2. Compared with unidirectional rolling technics, cross rolled molybdenum plate’s mechanical properties in vertical and horizontal two directions are better. In the case of matching strength, the elongation rate has been significantly improved.

3. Cross rolling will strengthen the uniformity of the internal structure of molybdenum plate. This kind of structure can maintain good plasticity in the further processing and has good deep drawing performance.