Tungsten has certain properties which must be taken into account when working the metal. A knowledge of these properties and of the following recommendations are prerequisites for successful working.

The recommended temperature range for these operations (bending, forming, stamping, punching and cutting) is above the brittle-ductile transition temperature and below the recrystallization temperature.

Thin, intensely worked sheet and foil, due to the preferred orientation of the grains from rolling in the longitudinal direction, have pronounced fibrous structures. Their bending properties, parallel and transverse to the rolling direction, differ considerably.

Generally we recommend that tungsten sheet is bent only transverse to the rolling direction. If bending along the longitudinal direction is unavoidable, the welding temperature must be increased considerably. The minimum bend radius is usually about the same as the sheet thickness.

At high temperatures, tungsten can also be worked by spinning, flow turning or forging.

Stamping of tungsten is also possible if the temperature of the sheet and the tools is correspondingly high.

Tungsten can be punched and sheared at elevated temperatures. Cracks and laminations can be caused by dull cutting edges of the upper punches and shears and by low cutting temperatures.

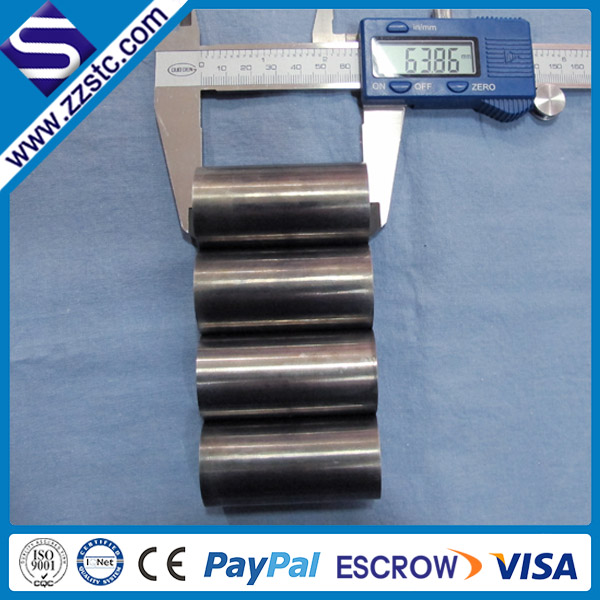

Zhengzhou Sanhui Co., Ltd has been dealing in refractory metals, like titanium, molybdenum, zirconium, for 25 years. We are one Alibaba 10-year golden supplier.

Come to Sanhui for standard or customized metal products.