How to improve the quality of the welding of titanium tube

Because the reactivity of titanium tube is strong, so in the welding of titanium tube, there are strict requirements to the welding temperature control, protection gas and welding environment, a slight mistake will have a greater impact on the welding quality, if it is serious, it will lead to product rejection. It has been proved by the practice that after analyzing the main factors which influence the welding quality, determining the welding key process, strengthening to control the environment, personnel, welding parameters and methods in the welding process can effectively ensure that the welding quality of titanium tube has been further improved, to prevent the appearance of welding scrap.

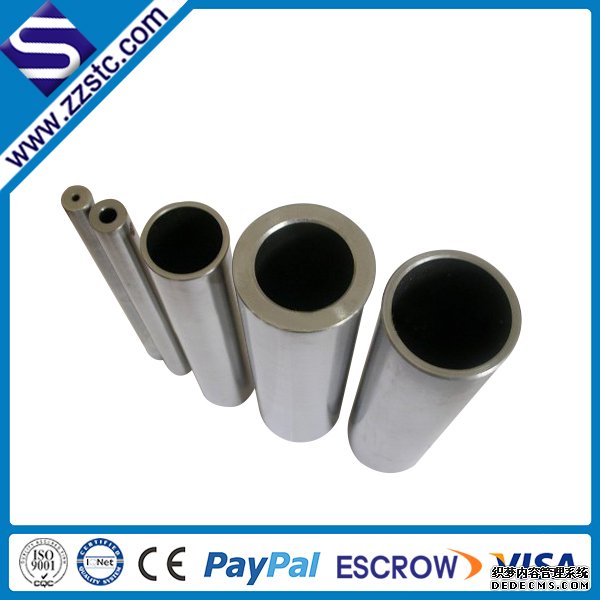

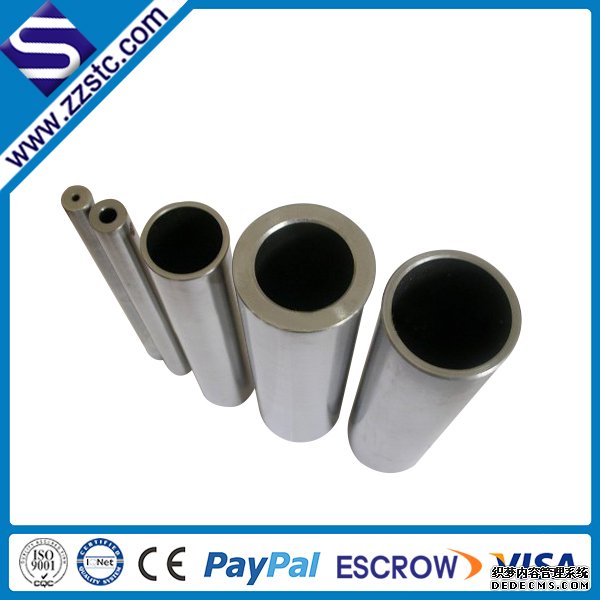

In recent years, a new titanium tube is widely used. Because the titanium alloy has the characteristics of light weight, high strength, corrosion resistance and other properties, in addition to be widely used in aerospace, petrochemical industry and machinery manufacturing, and other areas, it can also be used in the construction of piping of a surface ship for the first time. But because the titanium alloy is a kind of active metal, under the high temperature, it has great affinity with oxygen, hydrogen and nitrogen gas, namely absorption and dissolved gas ability are very strong, especially in the welding process, this ability is particularly strong with the welding temperature increased. It has proved that if the absorption and dissolution of titanium alloy to oxygen, hydrogen, nitrogen and other gases are not controlled, the final product will be scrapped. Therefore, it is necessary to prevent and control the welding of the titanium pipe joint to meet the quality requirements of the welding.

In recent years, a new titanium tube is widely used. Because the titanium alloy has the characteristics of light weight, high strength, corrosion resistance and other properties, in addition to be widely used in aerospace, petrochemical industry and machinery manufacturing, and other areas, it can also be used in the construction of piping of a surface ship for the first time. But because the titanium alloy is a kind of active metal, under the high temperature, it has great affinity with oxygen, hydrogen and nitrogen gas, namely absorption and dissolved gas ability are very strong, especially in the welding process, this ability is particularly strong with the welding temperature increased. It has proved that if the absorption and dissolution of titanium alloy to oxygen, hydrogen, nitrogen and other gases are not controlled, the final product will be scrapped. Therefore, it is necessary to prevent and control the welding of the titanium pipe joint to meet the quality requirements of the welding.